Fortifying Infrastructure: The Crucial Role of Screws in Geocell Soil Stabilization

Geocell soil stabilization is a critical technique in civil engineering, fortifying soil and enhancing infrastructure stability. Screws are pivotal components in this process, providing essential anchorage for geocells. This article explores the significance of screws in geocell soil stabilization, addressing common inquiries and offering insights into their importance.

Why are screws crucial in geocell soil stabilization?

Screws are crucial in geocell soil stabilization as they provide a secure anchoring mechanism for geocells. By penetrating the soil, screws securely hold the geocells in place, preventing shifts or movements, especially in areas prone to erosion or ground instability.

What types of screws are utilized in geocell soil stabilization?

Various types of screws are utilized based on project requirements. Common options include helical anchors, driven screws, and self-tapping screws. Each type offers specific benefits in terms of installation ease, load-bearing capacity, and adaptability to soil conditions.

How are screws integrated into geocell soil stabilization?

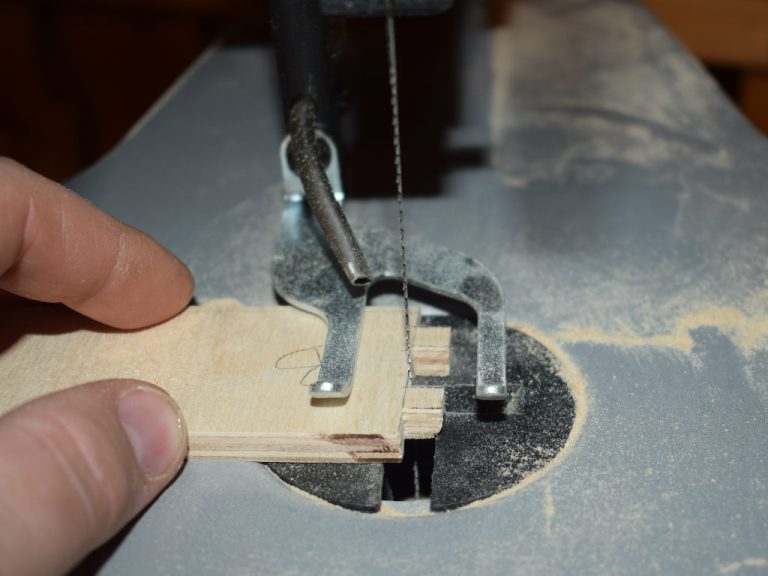

Screws are integrated by drilling or driving them into the ground at specified intervals along the perimeter and within the geocell structure. Specialized equipment such as hydraulic drivers or handheld screwdrivers ensures precise installation depth and torque.

What are the benefits of employing screws in geocell soil stabilization?

Employing screws in geocell soil stabilization provides several benefits, including reliable anchorage, enhanced stability, and improved load distribution. This extends the lifespan of infrastructure such as roads, embankments, and retaining walls. Moreover, screws offer cost-effectiveness and environmental friendliness compared to conventional methods.

In summary, screws play a crucial role in geocell soil stabilization by providing secure anchorage and enhancing infrastructure stability. Understanding the importance of screws and their proper installation techniques is essential for the success of geocell-based soil stabilization projects. Leveraging screws in geocell applications enables engineers to develop resilient and sustainable solutions for construction challenges.

Cameron Orbit Valve is a leading product known for its exceptional performance in critical applications within industries like oil and gas, petrochemical, and power generation. The Orbit Valve series by Cameron offers advanced solutions for severe service conditions, featuring high pressure and temperature capabilities, tight shutoff, and minimal maintenance requirements. With a focus on durability and reliability, Cameron Orbit Valves are engineered to withstand harsh operating environments and ensure long-term operational efficiency. The precision design and quality construction of Cameron Orbit Valves make them a trusted choice for demanding applications where safety, performance, and longevity are essential.